Two-Stage Oil-injected Screw Air Compressor

Description

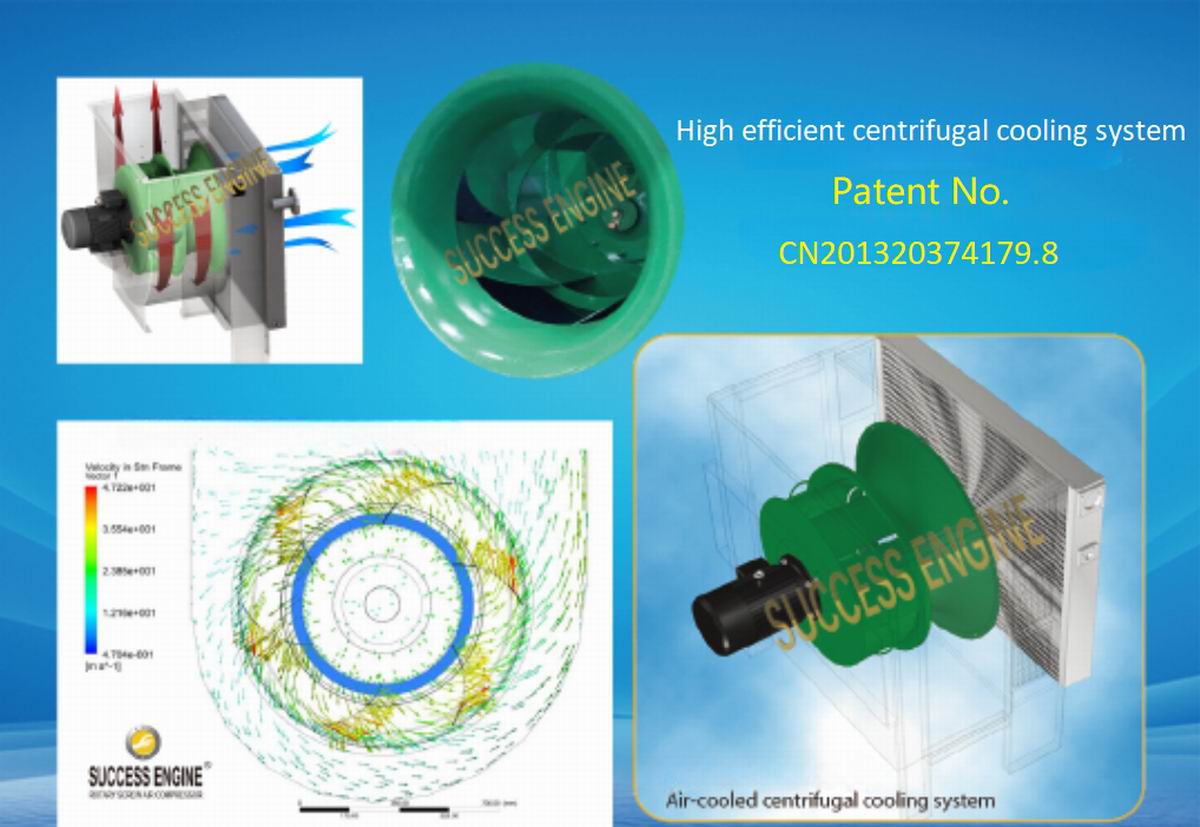

SUCCESS ENGINE energy-saving screw air compressor has two core patents - large-diameter rotor profile design and high-efficiency centrifugal cooling system, which greatly improves the compression and volumetric efficiency. The product has been tested by third-party, the volume flow and input power meet the requirements of the energy-saving evaluation value, and it is rated as an energy-saving product.

The energy-saving screw air compressor adopts high-efficiency special motor with high-quality bearings. According to the customer's power supply conditions, it can choose to match various motors of different voltage & frequency, permanent magnet type, explosion-proof, dust-proof, etc.

With ingenious design, high-standard configuration, and excellent value for money, SUCCESS ENGINE is proud of its quality. Please continue to browse the detailed introduction, we believe that you will have your own choice!

Reliable, Ultra-Efficient Performance

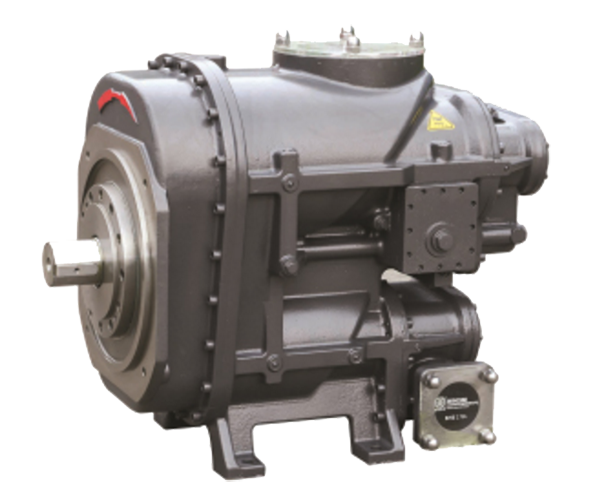

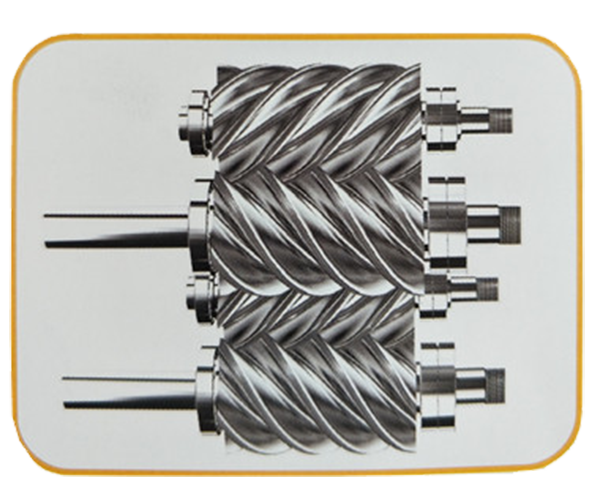

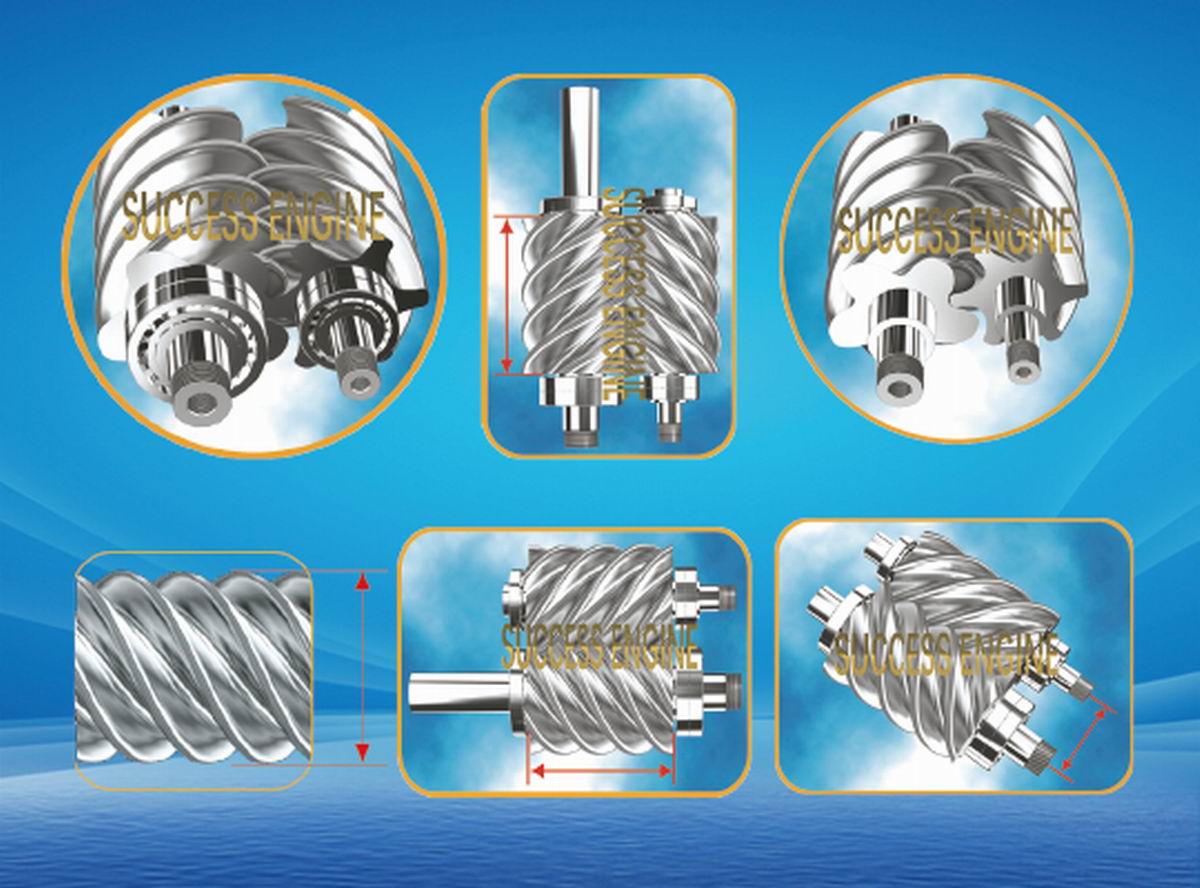

Use the newest UV rotor of profile line with large diameter and low speed. The two pairs of rotors are independent of the two compression units, the primary compression rotor and the secondary compression rotor are combined in same compressor housing. Respectively, through the gear drive, the two inter-stage rotors are in the best line speed state of operation, and the compression efficiency is extremely high. This air compressor’s has smaller host compression ratio, less leakage, and the volume efficiency is higher than the single-stage compression of 15%, the energy-saving effect is remarkable.

Precise Control

Personalized intelligent control system, Intuitive Intellects controller gives you complete, fingertip access to your compressor, including easily adjustable operating parameters and time-saving on-board diagnostics.

Less-Leakage Design

Selection of high durability, strong bearing capacity of SKF heavy-duty bearing to ensure that the core components with excellent reliability and durability. Using O-ring fittings significantly reduces the potential leakage problems associated with conventional threaded fittings..

Flexible Design Options

Air-cooled or water-cooled, Standard and VSD type, Voltage & Frequency customized, Low Pressure (3~5 Bar)Soft starting option, mixed flow system temperature control valve.

|

MODEL |

Power (kW) |

Pressure(bar) |

Air Flow (m3/min) |

Outlet Connection |

Cooling water/air capacity (air -kw;warter-m3/h) |

Weight (Kg) |

Dimension L×W×H mm |

| SE22AE-7 SE22AE-10 SE22AE-12.5 |

22 |

7 10 12.5 |

4.20 3.80 3.20 |

Rp 1 1/4 |

* |

680 |

1470x860x1340 |

| SE37E-7 SE37AE-10 SE37AE-12.5 |

37 |

7 10 12.5 |

7.10 6.60 5.80 |

Rp 1 1/2 |

* |

920 |

1610x1000x1470 |

| SE55AE-7 SE55AE-10 SE55AE-12.5 |

55 |

7 10 12.5 |

11.60 11.20 9.10 |

Rp 2 |

* |

1620 |

2100x1200x1680 |

| SE75AE-7 SE75AE-10 SE75AE-12.5 |

75 |

7 10 12.5 |

15.80 14.20 11.60 |

Rp 2 |

* |

1980 |

2100x1200x1680 |

| SE90AE-7 SE90AE-10 SE90AE-12.5 |

90 |

7 10 12.5 |

20.50 17.60 14.20 |

DN 65 |

* |

2600 |

2500x1800x1800 |

| SE110AE-7 SE110AE-8 SE110AE-10 SE110AE-12.5 |

110 |

7 8 10 12.5 |

24.50 23.50 20.00 17.20 |

DN 65 |

Air-3.0kw Water-10m3/h |

3300 |

2500x1800x1800 |

| SE132AE-7 SE132AE-8 SE132AE-10 SE132AE-12.5 |

132 |

7 8 10 12.5 |

27.60 26.60 23.50 19.60 |

DN 65 |

Air-3.0kw Water-12m3/h |

3550 |

2500x1800x1800 |

| SE160AE-7 SE160AE-8 SE160AE-10 SE160AE-12.5 |

160 |

7 8 10 12.5 |

33.50 32.50 29.00 23.20 |

DN 80 |

Air-3.5kw Water-15m3/h |

4000 |

3000x1800x1800 |

| SE185AE-7 SE185AE-8 SE185AE-10 SE185AE-12.5 |

185 |

7 8 10 12.5 |

39.50 38.00 32.50 27.80 |

DN 80 |

Air-3.5kw Water-15m3/h |

4200 |

3000x1800x1800 |

| SE220A(W)E-7 SE220A(W)E-8 SE220A(W)E-10 SE220A(W)E-12.5 |

220 |

7 8 10 12.5 |

46.60 45.00 41.50 38.20 |

DN 100 |

Air-5.5kw Water-20m3/h |

6500 |

3200x2200x2300 |

| SE250A(W)E-7 SE250A(W)E-8 SE250A(W)E-10 SE250A(W)E-12.5 |

250 |

7 8 10 12.5 |

52.00 50.50 45.50 40.20 |

DN 125 |

Air-7.5kw Water-25m3/h |

7200 |

3200x2200x2300 |

| SE280A(W)E-7 SE280A(W)E-8 SE280A(W)E-10 SE280A(W)E-12.5 |

280 |

7 8 10 12.5 |

60.00 58.50 51.00 43.50 |

DN 125 |

Air-7.5kw Water-30m3/h |

9000 |

3200x2200x2300 |

| SE315A(W)E-7 SE315A(W)E-8 SE315A(W)E-10 SE315A(W)E-12.5 |

315 |

7 8 10 12.5 |

65.00 63.00 59.00 53.00 |

DN 125 |

Air-7.5kw Water-30m3/h |

9200 |

3200x2200x2300 |

| SE355A(W)E-7 SE380A(W)E-8 SE400A(W)E-10 |

355 380 400 |

7 8 10 |

73.20 72.90 72.60 |

DN 200 |

Air-11kw Water-35m3/h |

9500 |

5060x2350x2400 |

| SE400A(W)E-7 SE430A(W)E-8 SE450A(W)E-10 |

400 430 450 |

7 8 10 |

82.50 82.20 81.60 |

DN 200 |

Air-15kw Water-45m3/h |

10000 |

5060x2350x2400 |

| SE500A(W)E-7 SE540A(W)E-8 SE570A(W)E-10 |

500 540 570 |

7 8 10 |

102.00 101.60 101.20 |

DN 200 |

Water-55m3/h |

10500 |

5060x2350x2400 |

(VSD/VFD type is available, please consult with sales)

Energy-saving screw air compressor (Flow: 3.0~100m³/min, pressure: 2~35bar)

|

|

| Core technology innovationMesh and seal innovation: Precise meshing and sealing of the rotor bottom profile – improve volumetric efficiency. Innovations of tooth root profile – improve air production efficiency, innovation of length and diameter ratio – Improve the overall rotor rigidity, innovation of shaft distance – prolong the bearing service life. | High-efficiency compressor airend (Patent No: CN201320374188.7)By optimizing the rotor profile which greatly improves the effective volume, sealing and gas production efficiency. Large diameter and low speed rotor, equipped with heavy-duty bearings and three special shaft seals to ensure the highest gas production efficiency and service life, and greatly reduce radial vibration and airflow noise. |

Advanced screw rotor processing equipment

The advanced rotor processing equipment is used to process the rotor in multiple processes to accurately ensure that the rotor profile and precision meet the design requirements and are absolutely reliable, so that the core technology of SUCCESS ENGINE remains in a leading position.

Strict rotor dynamic balance test

Using advanced dynamic balancing equipment, according to the requirements of “Success Engine Dynamic Balance Test Procedure”, a strict dynamic balance test is carried out on each rotor to ensure the rotor balance accuracy level, ensure the balance and stability during full-speed operation, and improve the overall performance of the compressor.

Strict accuracy inspection and hydraulic test of compressor components

The three-coordinate measuring instrument is used to carry out strict precision inspection on the compressor airend casing, end cover and other components, and the pressure-bearing components are subjected to a 30 minutes hydraulic test of 1.25 times the design pressure. Only those products that meet the inspection standards and technical requirements can be judged as qualified products.

|

|

| High efficient centrifugal cooling systemThe aerodynamic calculation and full three-dimensional flow simulation are carried out, combined with actual operation data to optimize the volute structure and fan blade profile, to save power, increase dynamic pressure, and achieve the best fan efficiency.Adopts side-entry & top-discharge closed frequency conversion fan cooling structure. Equip with centrifugal fan, the frequency conversion automatically adjusts the fan speed according to the system temperature change. | High efficient water cooling systemFor high-power unit, unique shell-and-tube baffle and tube-column was designed and installed, effectively improves the heat exchange rate between compressed air and water, and reduces the water consumption.For low-power unit, the plate corrugated superimposed structure can be selected, so that the fluid can form turbulent flow, size is small but with good heat dissipation effect. |

High-efficiency electric motor

Use special high output efficiency motor with high-quality bearings according to the site power supply and process conditions, and available for different voltage, frequency, protection level, insulation level, service factor, VFD, explosion-proof and other required types.

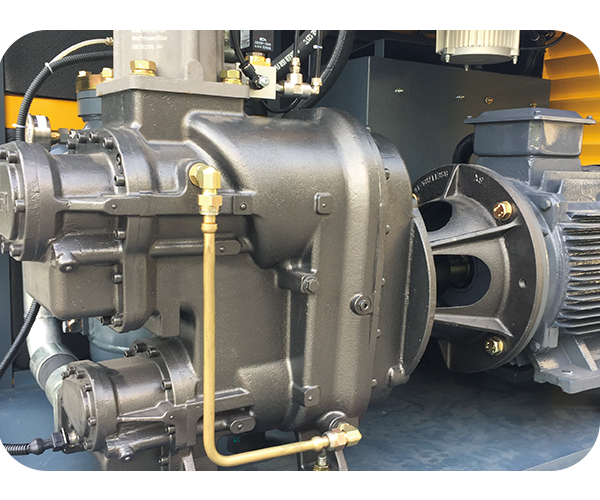

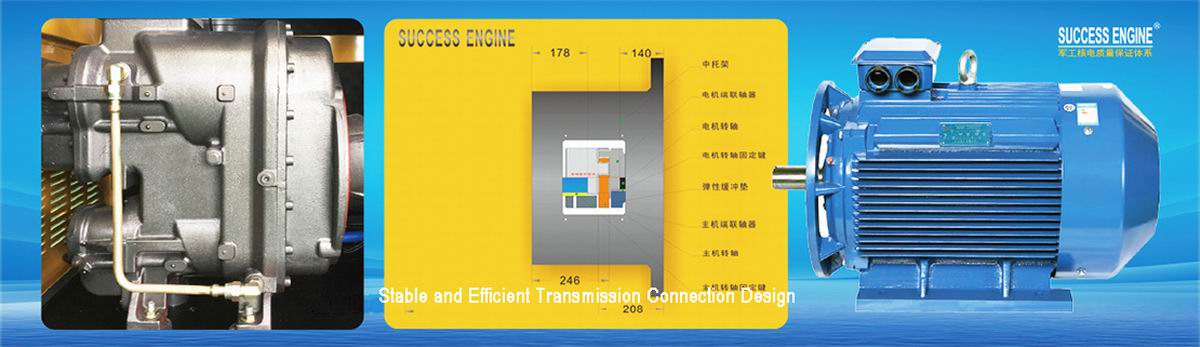

SUCCESS ENGINE adopts a high-strength intermediate coupling combined with a high-load elastic coupling device. The coupling bracket plays a stable role, and the elastic coupling plays a role in transmitting rotational torque, compensating axis offset, absorbing vibration and reduces loading impact. This structure has the advantage of high transfer efficiency, noise reduction and easy maintenance.

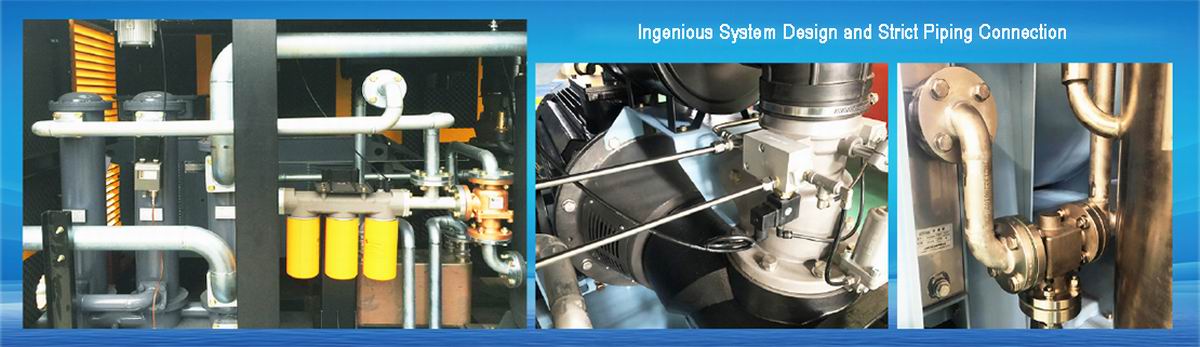

Ingenious system design and strict piping connection

SUCCESS ENGINE pays special attention to piping system design, sealing effect and pressure difference of each part, and has carried out a special optimization design for the pressure-bearing parts. Flange welding and non-destructive evaluation (NDE) has been used for sealing connections as much as possible. The threaded connection adopts SAE joints by standard of AAMA to ensure the sealing and durability of the system pipeline.

Efficient oil & air separation device and lubricating medium

Double-layer pleated oil-air separation element and rough oil & gas separation tank, ensuring the best oil and gas separation effect and the lowest system pressure difference.

SUCCESS ENGINE special cooling oil- MSDS (Material Safety Data) complies with the ISO 14001 environmental protection standard, high temperature resistance and anti-oxidation properties extend the life of core parts.

Ingenious design, faithful what it seems

High-quality parts configuration, superior system structure design and ingenious manufacturing requirements make SUCCESS ENGINE screw air compressor living up to its reputation, reliable and durable.

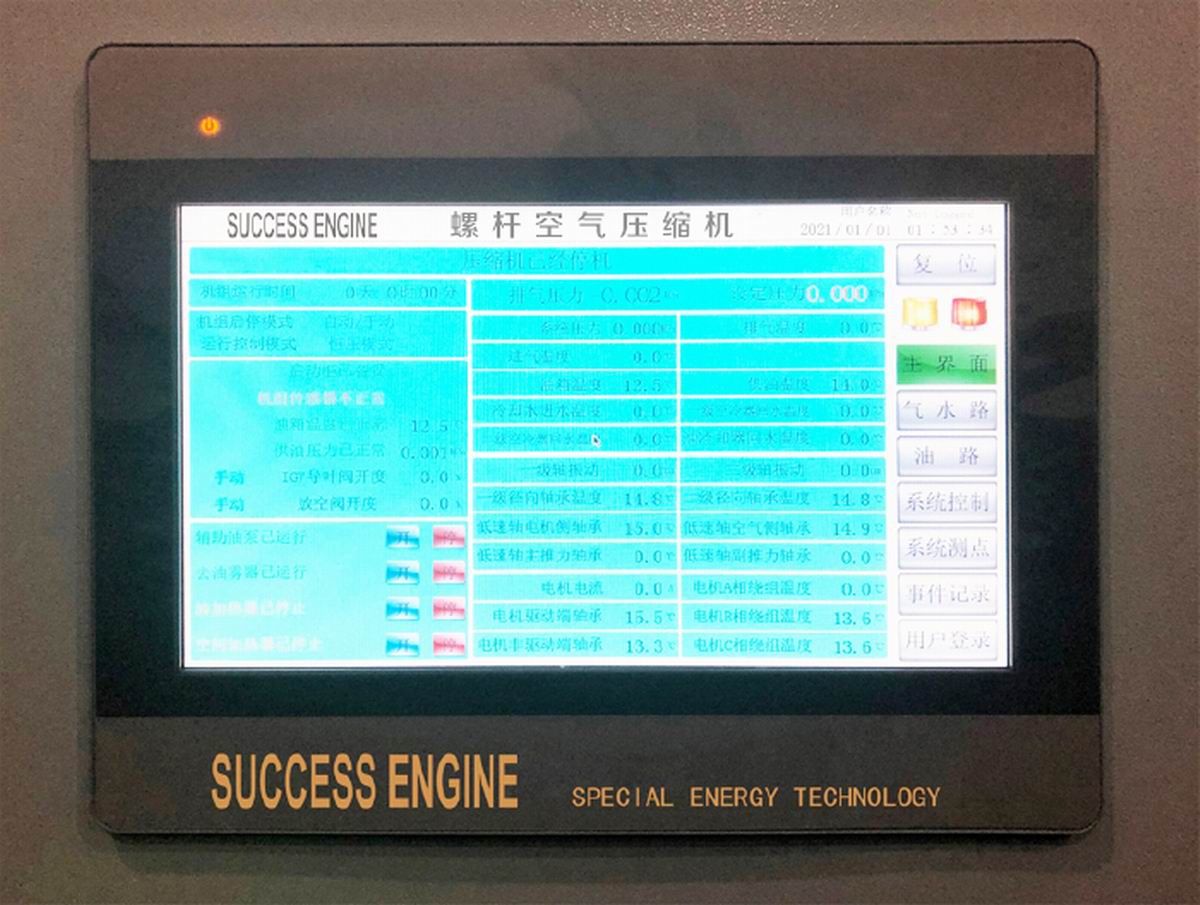

Intelligent control (standard)

Adopt advanced intelligent control system with complete functions of automatic protection & alarm, remote control, multiple joint control, history records. (1) Real-time running data. (2) Monitor loading/unloading characteristics. (3) Preset various parameter values. (4) History records checking and display maintenance warning.

Equipped with one 485 interface, to realize two communication control modes: general remote and linkage control. The user can set the linked control of multiple units and manually set the unit to start/stop and time switching.

Frequency conversion control/soft start control (optional)

Low-voltage unit: built-in structure, with optional of VFD control and dual-purpose controls (Standard + VFD). High-voltage unit: divided structure, separated external high-voltage frequency conversion cabinet.

Compressor atomically adjusts the frequency and speed according to the actual air consumption change to achieve effective energy savings, also with the characteristics of stable air pressure, startup without impact.、

|

|

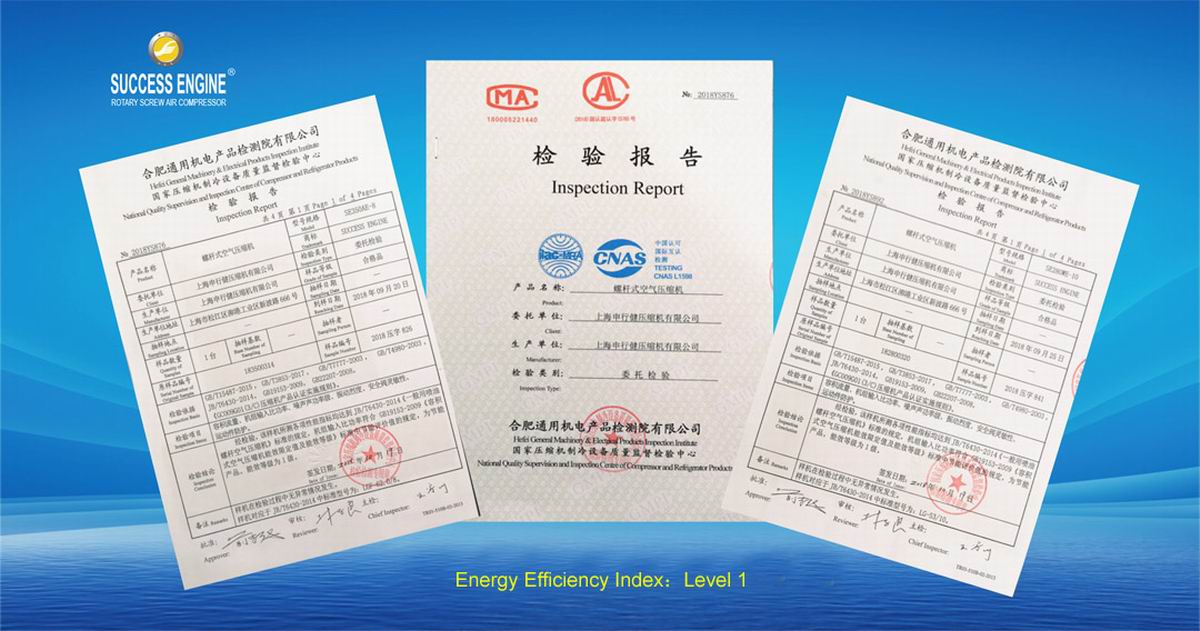

Energy efficiency test (Factory inspection, praise for level-1 energy efficiency)

SUCCESS ENGINE has its own energy efficiency lab. Each air compressor has undergone strict full performance testing, only when it meets the requirements of various indicators, can be labeled as qualified.

Perfect optimization of the SUCCESS ENGINE energy-saving air compressor system is a model for improving the two major needs of “energy-efficiency ratio” and “quality reliability” in the field of civil energy and power, leading the new generation of gas source power.

|

|

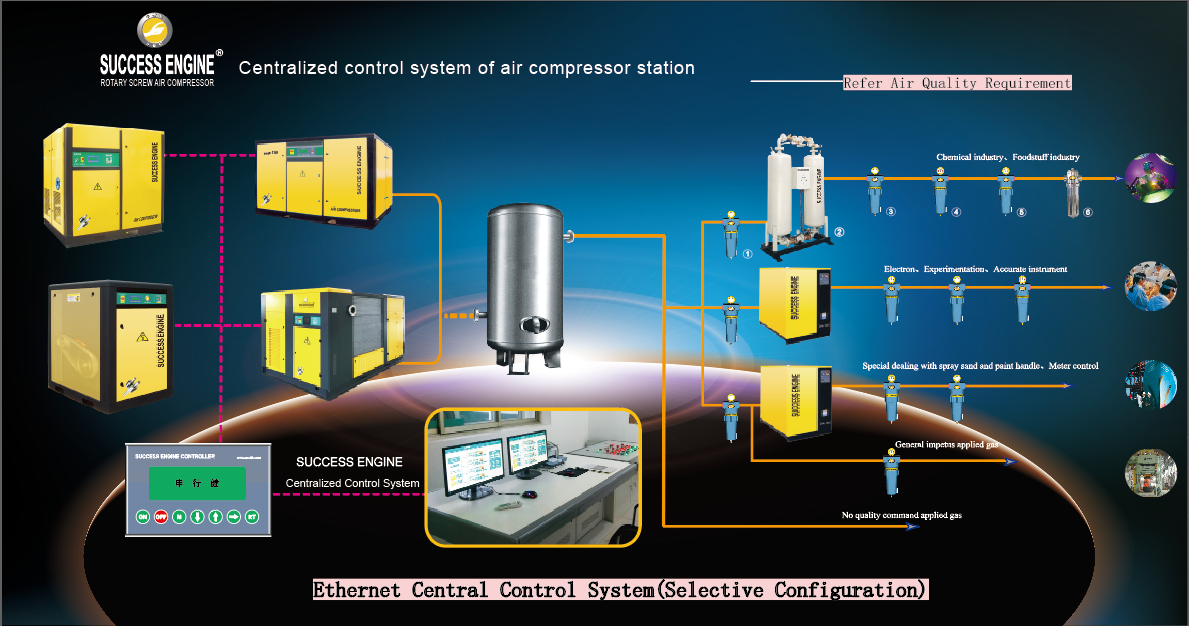

Ethernet central control system (optional)

The centralized compressor control system communicates with the monitoring station through the industrial Ethernet ring network, performs remote monitoring and intelligent control of the equipment in the air compressor room, and realizes automatic unattended operation.

Configuration: linkage control PLC system, control cabinet, UPS, wireless communication equipment, video monitoring system, voice broadcasting system, computer operation station, display, printer, work table.

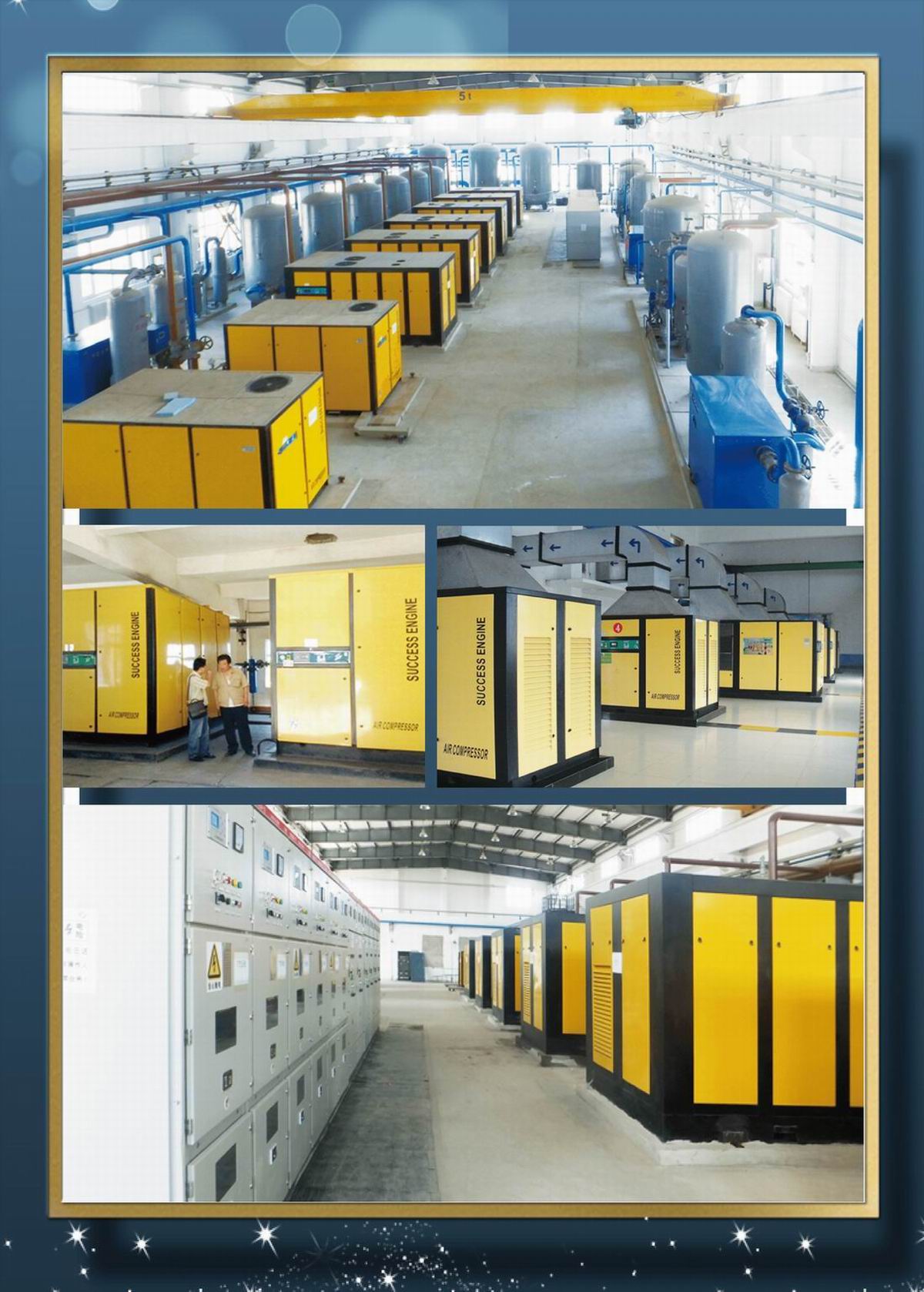

Large-power energy-saving air compressor loading & delivery

SUCCESS ENGINE energy-saving screw air compressors, relying on leading technical advantages, military nuclear power-grade quality assurance system and lots of marketing and after-sales channel, continue to enter high-end industry applications around the world

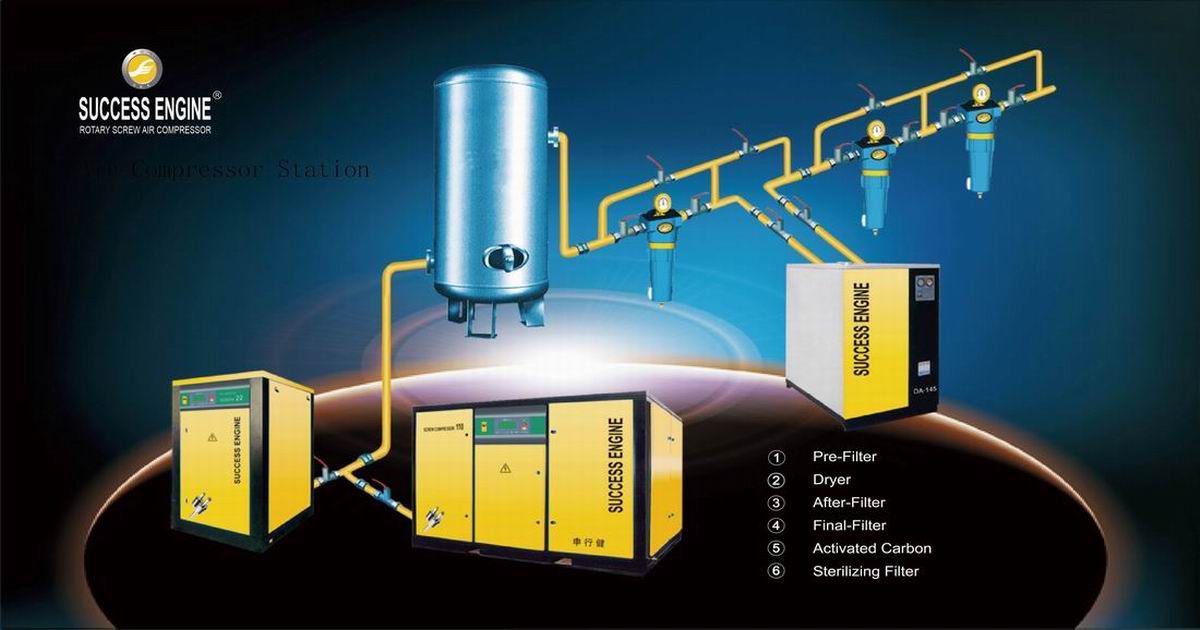

Standard Air Compressor Station

Installation and Use Site

Assembly Workshop

Ethernet central control system (optional)

The centralized compressor control system communicates with the monitoring station through the industrial Ethernet ring network, performs remote monitoring and intelligent control of the equipment in the air compressor room, and realizes automatic unattended operation.

Configuration: linkage control PLC system, control cabinet, UPS, wireless communication equipment, video monitoring system, voice broadcasting system, computer operation station, display, printer, work table.

Processing Workshop