Efficient & Energy-saving Large-scale Centrifugal Compressor

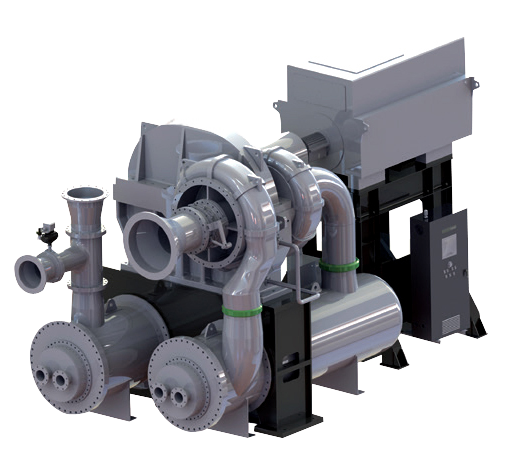

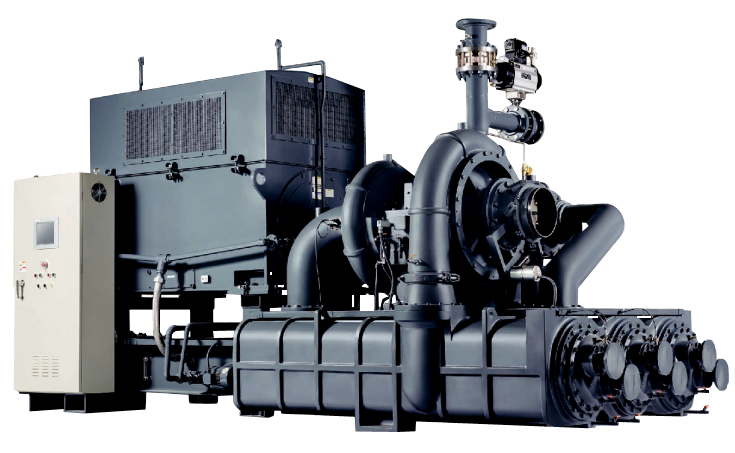

Centrifugal Compressor

How does SUCCESS ENGINE centrifugal compressor work?

Air is drawn into the center of a rotating impeller with radial blades and is pushed toward the center by centrifugal force. This radial movement of air results in a pressure rise and the generation of kinetic energy. Before the air is led into the center of the impeller, the kinetic energy is also converted into pressure by passing through a diffuser and volute.

Each stage takes up a part of the overall pressure rise of the compressor unit. Depending on the pressure required for the application, a number of stages can be arranged in a series to achieve a higher pressure. This type of multi-stage application is often used in the oil and gas and process industries. Alternately, in wastewater treatment plants, low pressure, single-stage applications are used to achieve the desired pressure ratio.

In modern configurations of SUCCESS ENGNIEN centrifugal air compressors, ultra-high speed electric motors are used to drive the impellers. This results in a compact compressor without a gearbox and associated oil-lubrication system, thus making it oil-free and appropriate for applications that require 100 percent oil-free air.

Specifications

|

Standard Input Power |

150 to 6000 kW |

202.5 to 8,100 hp |

|

Discharge Pressure |

1 to 25 bar |

14.5 to 362.5 psig |

|

Inlet Flow |

40 to 800 m3/min |

1,412 to 28,240 CFM |

Specifications

(Small Type)

(Bigger Type)

|

Model |

Power (KW) |

Volume Flow Rate (M3/min) |

Ultimate Vacuum kPa(G) |

Connection |

Weight (KG) |

Dimension (L x W x H) mm |

|

SEV5A-100 |

5.5 |

6.5 |

-100 |

DN40 |

430 |

1200X1100X1250 |

|

SEV5A-080 |

6.3 |

-80 |

||||

|

SEV7A-100 |

7.5 |

9.6 |

-100 |

DN40 |

600 |

1200X1100X1250 |

|

SEV7A-080 |

9.5 |

-80 |

||||

|

SEV11A-100 |

11 |

12.5 |

-100 |

DN50 |

760 |

1400X1100X1450 |

|

SEV11A-080 |

12.0 |

-80 |

||||

|

SEV15A-100 |

15 |

15.0 |

-100 |

DN50 |

900 |

1500X1200X1650 |

|

SEV15A-080 |

14.6 |

-80 |

||||

|

SEV18A-100 |

18.5 |

18.0 |

-100 |

DN65 |

960 |

1500X1200X1650 |

|

SEV18A-080 |

17.6 |

-80 |

||||

|

SEV22A-100 |

22 |

22.5 |

-100 |

DN80 |

1100 |

1850X1450X1800 |

|

SEV22A-080 |

22.0 |

-80 |

||||

|

SEV30A-100 |

30 |

27.5 |

-100 |

DN100 |

1600 |

2150x1600x2100 |

|

SEV30A-080 |

27.0 |

-80 |

||||

|

SEV37A-100 |

37 |

30.5 |

-100 |

DN100 |

1850 |

2350x1700x2154 |

|

SEV37A-080 |

30.0 |

-80 |

||||

|

SEV45A-100 |

45 |

45.0 |

-100 |

DN125 |

1900 |

2350x1700x2154 |

|

SEV45A-080 |

44.5 |

-80 |

||||

|

SEV55A-100 |

55 |

60.0 |

-100 |

DN150 |

2200 |

3200x2150x2645 |

|

SEV75A-100 |

75 |

76.0 |

-100 |

DN200 |

3500 |

3200x2150x2645 |

|

SEV90A-100 |

90 |

85.0 |

-100 |

DN200 |

3600 |

3300x2250x2700 |

Centrifugal compressor & blower

SUCCESS ENGINE is specializing in the field of civil impeller machinery, focusing on the two major requirements of “energy efficiency ratio” and “quality reliability”, and has gathered domestic first-class engineer on aviation power, impeller machinery and suspension bearing. Using high-level advanced tools, software and equipment, through continuous self-development and innovation, it leads the civil impeller machinery industry to improve its innovation capabilities.

SUCCESS ENGINE centrifugal compressor has large flow, with high efficiency and no oil discharge. It is high-speed impeller mechanical equipment customized according to the user’s process requirements.

Centrifugal compressor: Flow: 40~1500 m3/min, Pressure: 2~25bar

GDC series gear-driven centrifugal compressors, centrifugal blowers are widely used in various industries which have the requirement for large-flow and continuous operation.

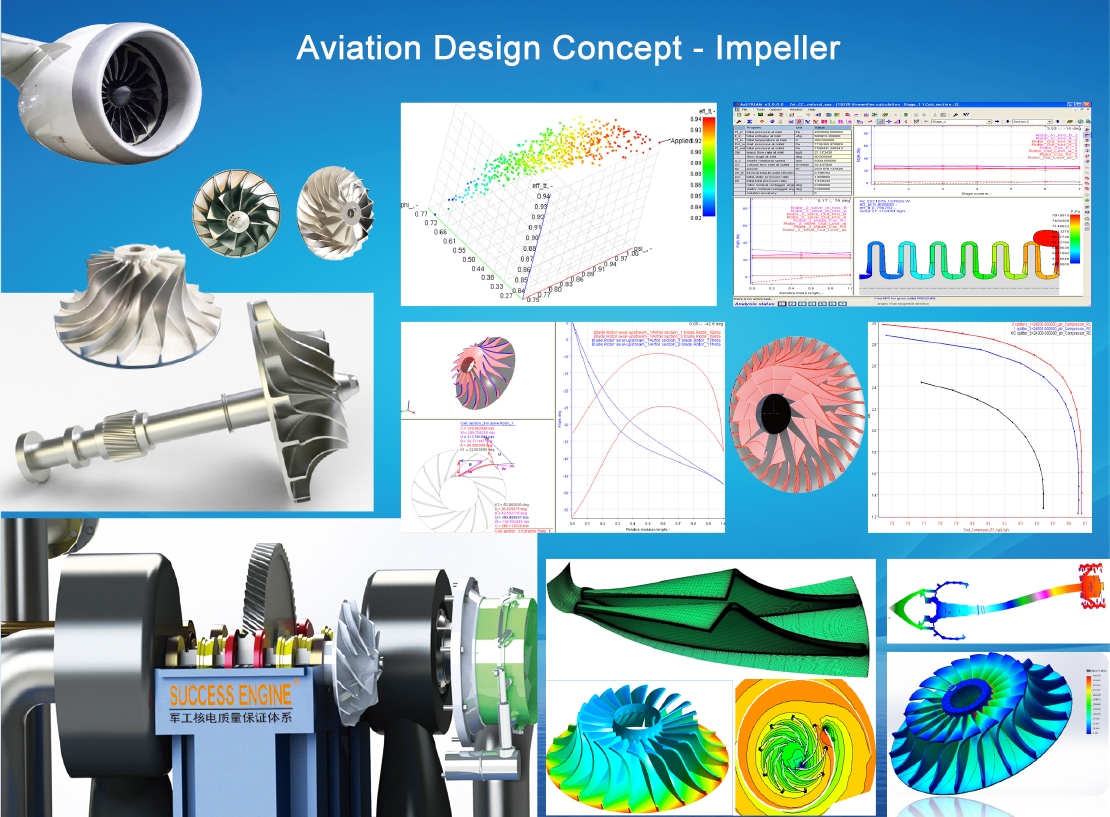

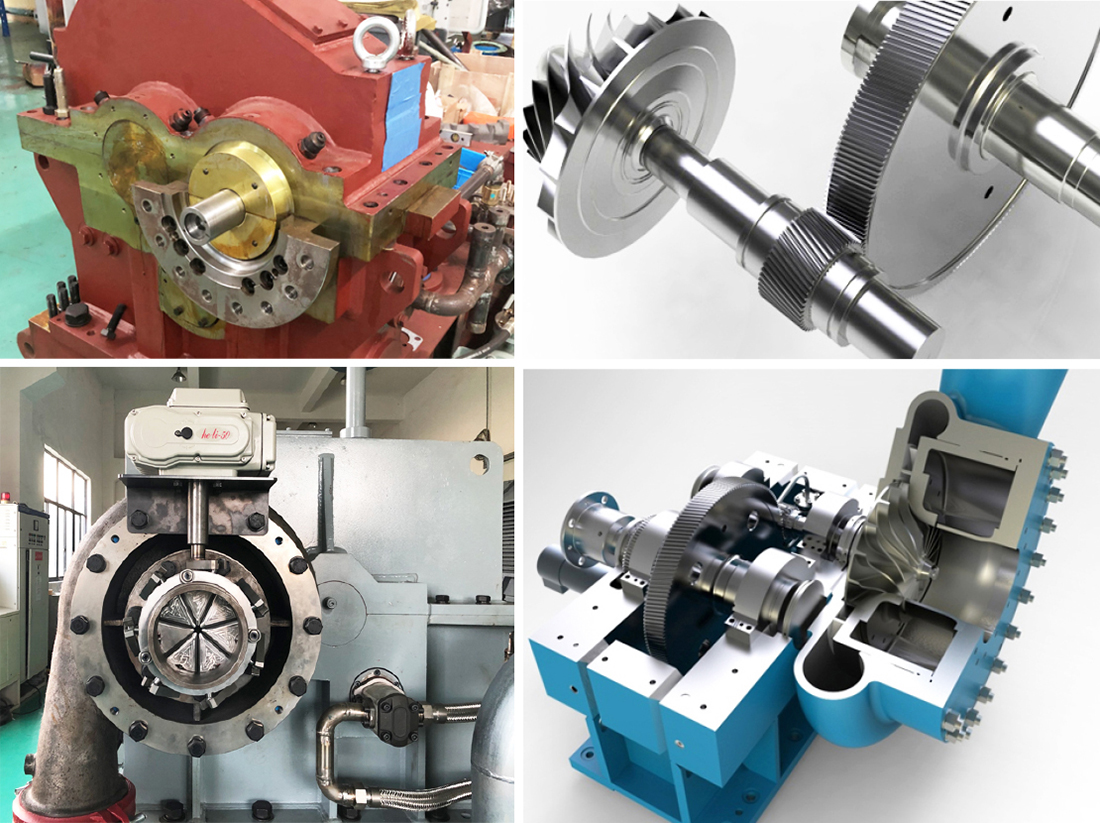

Aviation design concept – Impeller

Using finite element analysis software of NASTRAN, ANSYS, Abaqus, etc., to carry out one-dimensional geometric and thermal design, two-dimensional flow design, three-dimensional blade design and strength check of impellers and blades. Through simulation, it can be judged whether the impeller design meets the design standards of aero-engine, and the service life of the impeller can be predicted. Create high-efficiency aviation-grade impellers with the best “power energy efficiency ratio”.

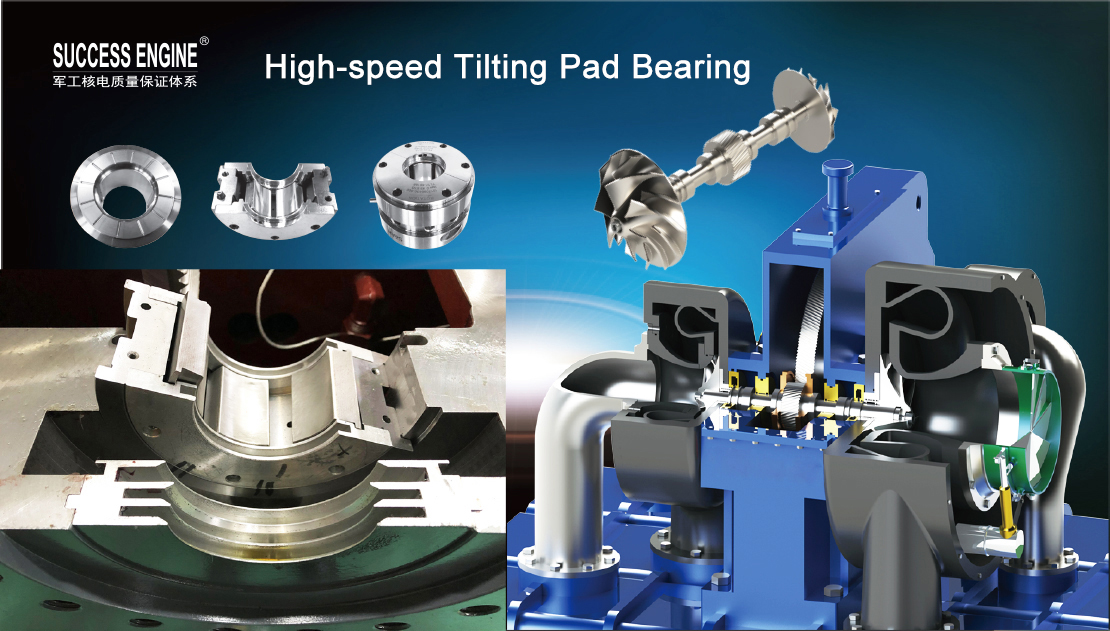

High speed titling-pad bearing

Adopt horizontal split-type tilting-pad bearing which made by material of ISI 1040 carbon steel (inner) and babbitt alloy (surface), when the speed load changes, the bearing diagonal block is automatically centered, this automatic adjustment function can ensure the machine’s smooth operation.

Aviation standard high speed gearbox

Horizontal split gearbox structure is used with aviation standard processing, manufacturing, debugging and inspection, with built-in high-speed forged alloy steel precision helical gears, the horizontal center divides the cylinder into upper and lower halves and connect by bolts, modular structure design is convenient for maintenance and repair.

Efficient removable cooler and intake air adjustment

The cooler is separated from the gearbox, and the lubrication system is perfectly separated from the compressed air, ensuring that the compressed air is 100% clean and oil-free. Removable cooler, tube bundles is precisely matched with the finished shell, which can effectively improve the heat exchange rate between compressed air and water and reduce the consumption of cooling water.

By adjusting the installation angle of inlet guide vane of the impeller, the pre-rotation of airflow can be adjusted within a range of 70-105%.

Impeller dynamic balance test

Using advanced dynamic balance testing equipment, according to the requirements of “SUCCESS ENGINE Dynamic Balance Test Procedure”, a strict dynamic balance testing is carried out on each impeller and shaft assembly to ensure the balance and stability during high-speed operation.