Dry Type Oil-Free Screw Air Cmpressor

Description

Dry type oil-free compressors (working pressure: 1.5 ~ 10 bar) are used in special processing fields, such as electric power, metallurgy, electronics, aviation, chemical, papermaking, Pharmaceutical, food, bottle blowing and cap making.

Dry type oil-free air blowers (working pressure: 0.4 ~ 1.5 bar) are used in sewage treatment, oxidation desulfurization, pneumatic conveying and other fields. In the field of aeration, the pressure can be automatically adjusted according to the change of water depth, and due to the wide range of working pressure adjustment, strong dust resistance, high efficiency and stability performance. It has become the most economical blower for the transformation of roots blowers.

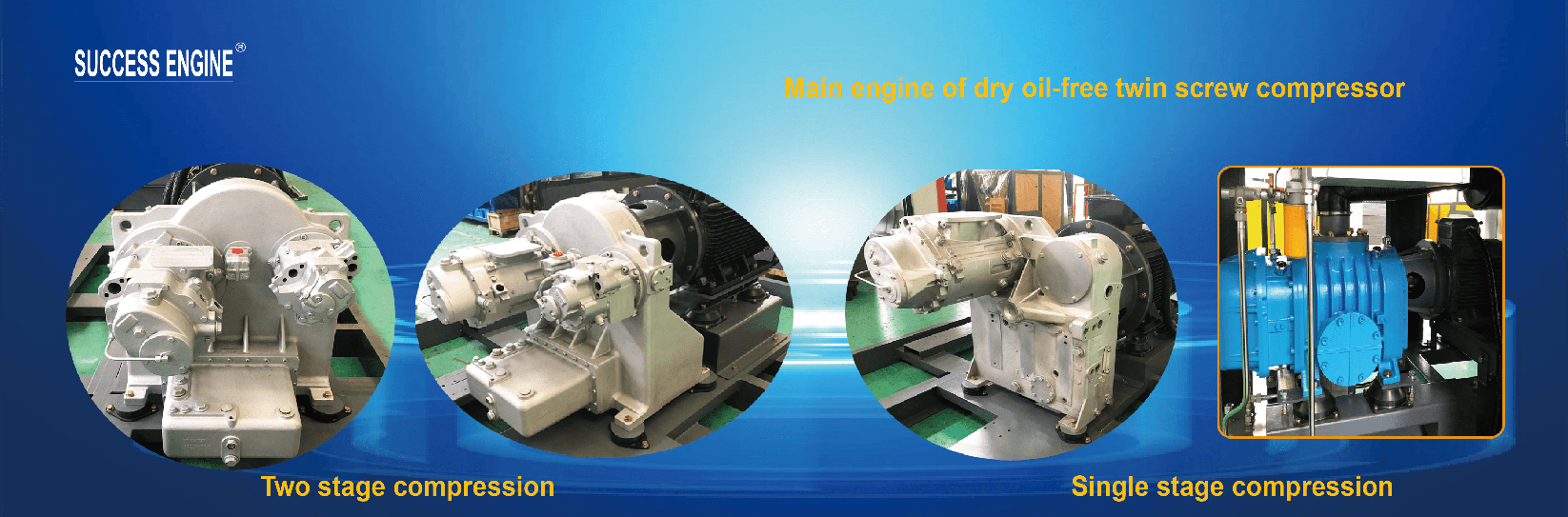

SUCCESS ENGINE oil-free screw compressor and air blower adopts dry type single-stage or double-stage compression, and the main airend is rotated by the coupling, in the compression chamber, there is no other liquid involved, so the compressed air is clean and oil-free.

Low Pressure Dry Type Oil Free Air Compressor

|

Model |

Power kW |

Pressure Bar |

Air Flow m3/min |

Outlet Connection |

Weight KG |

Dimension L*W*H mm |

|

ZA75(W)-1.5 |

75 |

1.5 |

20 |

DN65 |

2100 |

2900*2300*1880 |

|

ZA75(W)-2(2.5) |

2(2.5) |

19(17) |

||||

|

ZA75(W)-3 |

3 |

16 |

||||

|

ZA100(W)-1.5 |

100 |

1.5 |

32 |

DN80 |

2300 |

2900*2300*1880 |

|

ZA100(W)-2(2.5) |

2(2.5) |

29(26) |

||||

|

ZA100(W)-3 |

3 |

21 |

||||

|

ZA120(W)-1.5 |

120 |

1.5 |

34 |

DN80 |

2600 |

2100*2300*2050 |

|

ZA120(W)-2(2.5) |

2(2.5) |

33(29) |

||||

|

ZA120(W)-3 |

3 |

26 |

||||

|

ZA150(W)-1.5 |

150 |

1.5 |

38 |

DN100 |

3000 |

3100*2300*2050 |

Standard Dry Type Oil Free Air Compressor

|

Model |

Power kW |

Pressure Bar |

Air Flow m3/min |

Outlet Connection |

Weight KG |

Dimension L*W*H mm |

|

ZA55A(W)-7 |

55 |

7 |

8.9 |

DN50 |

1500 |

2300*1300*1780 |

|

ZA55A(W)-8 |

8 |

7.8 |

||||

|

ZA55A(W)-10 |

10 |

7.4 |

||||

|

ZA75A(W)-7 |

75 |

7 |

12 |

DN50 |

1600 |

2300*1300*1780 |

|

ZA75A(W)-8 |

8 |

11.5 |

||||

|

ZA75A(W)-10 |

10 |

10.2 |

||||

|

ZA90A(W)-7 |

90 |

7 |

14 |

DN65 |

2600 |

3100*2300*2050 |

|

ZA90A(W)-8 |

8 |

13.5 |

||||

|

ZA90A(W)-10 |

10 |

12.5 |

||||

|

ZA110A(W)-7 |

110 |

7 |

17.2 |

DN65 |

2800 |

3100*2300*2050 |

|

ZA110A(W)-8 |

8 |

16.7 |

||||

|

ZA110A(W)-10 |

10 |

16.2 |

||||

|

ZA132A(W)-7 |

132 |

7 |

19.6 |

DN65 |

3100 |

3100*2300*2050 |

|

ZA132A(W)-8 |

8 |

19.2 |

||||

|

ZA132A(W)-10 |

10 |

18.2 |

||||

|

ZA160A(W)-7 |

160 |

7 |

23.8 |

DN80 |

3500 |

3300*2300*2150 |

|

ZA160A(W)-8 |

8 |

22.8 |

||||

|

ZA160A(W)-10 |

10 |

21.8 |

||||

|

ZA180A(W)-7 |

180 |

7 |

28.1 |

DN80 |

3800 |

3300*2300*2150 |

|

ZA180A(W)-8 |

8 |

26.8 |

||||

|

ZA180A(W)-10 |

10 |

24.8 |

||||

|

ZA220A(W)-7 |

220 |

7 |

35.6 |

DN100 |

6000 |

3500*2300*2350 |

|

ZA220A(W)-8 |

8 |

33.5 |

||||

|

ZA220A(W)-10 |

10 |

31.2 |

||||

|

ZA250A(W)-7 |

250 |

7 |

41.6 |

DN100 |

6200 |

3500*2300*2350 |

|

ZA250A(W)-8 |

8 |

40.5 |

||||

|

ZA250A(W)-10 |

10 |

37.2 |

Dry type oil-free compressors (working pressure: 1.5 ~ 10 bar) are used in special processing fields, such as electric power, metallurgy, electronics, aviation, chemical, papermaking, Pharmaceutical, food, bottle blowing and cap making.

Dry type oil-free air blowers (working pressure: 0.4 ~ 1.5 bar) are used in sewage treatment, oxidation desulfurization, pneumatic conveying and other fields. In the field of aeration, the pressure can be automatically adjusted according to the change of water depth, and due to the wide range of working pressure adjustment, strong dust resistance, high efficiency and stability performance. It has become the most economical blower for the transformation of roots blowers.

SUCCESS ENGINE oil-free screw compressor and air blower adopts dry type single-stage or double-stage compression, and the main airend is rotated by the coupling, in the compression chamber, there is no other liquid involved, so the compressed air is clean and oil-free.

Dry type compressor airend

Due to the high temperature generated by the high-speed operation in air compression, the compressor shell is designed with a double-wall structure, and the interlayer is used for cooling oil (air cooling unit) or cooling water (water cooling unit) circulation. In the compression chamber, the hot air is compressed by twin-screw and discharged after being cooled by air cooler.

The rotor adopts the latest rotor patented type line design, the accuracy and reliability are guaranteed after more than 20 processes of finishing.

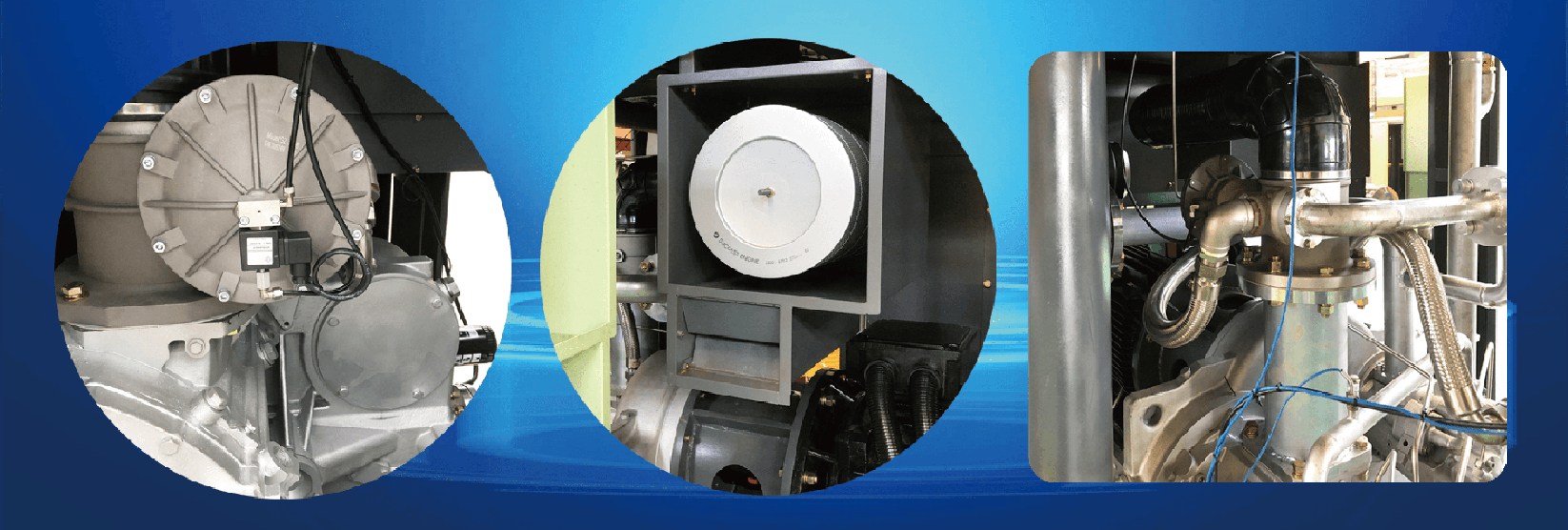

High efficient centrifugal cooling system(Patent No.:CN201320374179.8)

The air-cooled unit adopts side-entry & top-discharge closed frequency conversion fan cooling structure: through the installed centrifugal fan, the inverter automatically adjusts the fan speed according to the system temperature change, so as to achieve stable and uniform wind pressure.

High efficient liquid cooling system

For high-power unit, unique shell-and-tube baffle and tube-column was designed and installed, effectively improves the heat exchange rate between compressed air and water, and reduces the water consumption.

For low-power machines, the plate corrugated superimposed structure can be selected, so that the fluid can form turbulent flow, size is small but with good heat dissipation effect.

High-efficiency electric motor

Use high output efficiency special motor with high-quality bearings, choose a matching motor according to the site power supply conditions and process conditions, and can choose different voltage, frequency, protection level, insulation level, service factor, variable frequency regulation speed, explosion-proof and other types according to user requirements.

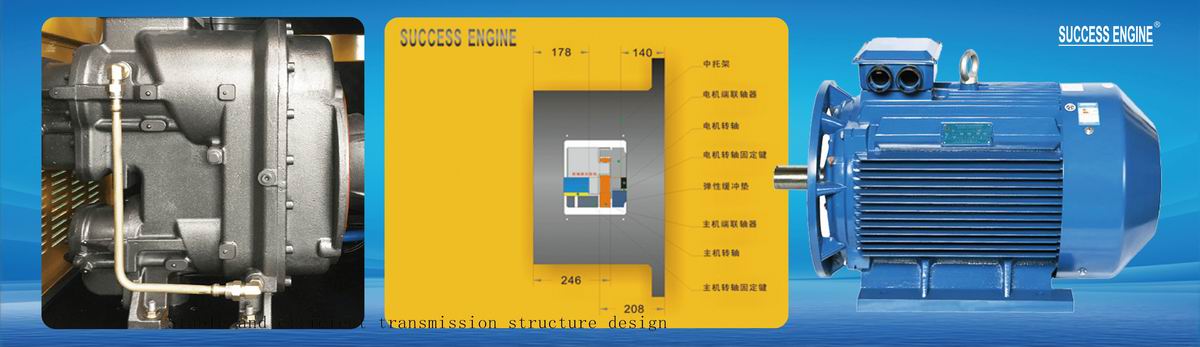

Stable and efficient transmission structure design

The low-power unit adopts belt drive structure, and the specially designed automatic tensioning device not only ensures the transmission efficiency, but also facilitates maintenance.

The high-power unit adopts a high-strength intermediate coupling combined with a high-load elastic coupling device. The coupling bracket plays a stable role, and the elastic coupling plays a role in transmitting rotational torque, compensating axis offset, absorbing vibration and reduces loading impact. This structure has the advantage of high transfer efficiency, noise reduction and easy maintenance.

Sophisticated system design and strict piping connection requirements

SUCCESS ENGINE pays special attention to the piping system design and the sealing effect and pressure difference of each part, and has carried out a special optimization design for the pressure-bearing parts, so as to minimize the system internal pressure loss. Flange welding and non-destructive evaluation (NDE) has been used for sealing connections as much as possible. The threaded connection adopts SAE joints of the standard of American Automobile Manufacturers Association to ensure the sealing and durability of the system pipeline.

Intelligent control (standard configuration)

Adopt advanced intelligent control system, complete functions such as automatic protection, automatic alarm, remote control, multiple joint control, history records, etc., to improve the operability and stability of the air compressor system: (1) Real-time running data. (2) Monitor energy consumption and loading/unloading characteristics. (3) Preset various parameter values according to the change of air consumption. (4) Display and check the preset changes of each parameter. (5) Check history records and display maintenance warning.

Equipped with one 485 interface, to realize two communication control modes: general remote and linkage. The user can set the linked control of multiple units such as A, B, and C according to the requirements, and manually set the unit to start/stop and time switching.

Frequency conversion control/soft start control (optional)

SUCCESS ENIGNE Oil free screw compressor & air blower low-voltage series: built-in structure, with optional of frequency conversion control and dual-purpose controls (power frequency/frequency conversion). High-voltage series: divided structure, separated external high-voltage frequency conversion cabinet.

The variable frequency air blower adjusts the speed of driving motor according to the actual air consumption change to achieve effective energy savings, also with the characteristics of stable air pressure, stable startup, variable flow and high operating efficiency.

Integrated cabinet construction

SUCCESS ENGINE oil-free screw compressor & air blower adopts twin-screw dry type oil-free compressor airend, which is composed of high-efficiency motor, gearbox, intake filter, silencer, cooler and frequency conversion intelligent control system, which can realize local and remote control, integrated cabinet structure, convenient for installation and maintenance.

Ingenious design, faithful what it seems

High-quality parts configuration, superior system structure design and ingenious manufacturing requirements make SUCCESS ENGINE compressor products living up to its reputation, reliable and durable.

We have power frequency, permanent magnet frequency conversion, high & low voltage, different voltage & frequency, water & air cooling and other complete products, which can meet the needs for all industries.

Factory Workshop

Product delivery and user site