High Speed Direct Driven Blower

High speed direct drive centrifugal compressor

It adopts advanced high-speed frequency inverter motor directly connected to drive the centrifugal impeller, without the power consumption of coupling and speed-increasing gearbox, without the necessary air or electric power consumption for suspension bearing, and the efficiency is extremely high.

It overcomes the special working pressure conditions and immature defects where the suspension bearing is difficult to apply. The integrated box structure has low requirements for the application environment, low maintenance costs, convenient installation, small space, and wide adaptability. It is the first choice of energy-saving equipment for 1.5-4Bar oil-free gas supply industry.

Advantage is our direct driven screw air compressor

High-speed variable frequency direct drive motor + centrifugal impeller structure, widely used in textile, fermentation and other Low & medium pressure gas supply industries.

It is most suitable for continuous gas working conditions of 1.5-4Bar pressure.

High efficiency: Compared with normal compressors, the efficiency is increased by 30%.

No pollution: the discharged air is clean, free of oil and pollution.

|

Model |

Pressure / Air Flow |

Power |

Outlet connection |

Dimension |

|

|

GD75 |

2 / 32 |

2.5 / 28 |

75 |

DN100 |

1080*1250*1800 |

|

3 / 25 |

4 / 21 |

||||

|

GD90 |

2 / 39 |

2.5 / 36 |

90 |

||

|

3 / 34 |

4 / 27 |

||||

|

GD110 |

2 / 40 |

2.5 / 38 |

110 |

||

|

3 / 43 |

4 / 30 |

||||

|

GD132 |

2 / 60 |

2.5 / 38 |

132 |

DN125 |

1250*1450*1900 |

|

3 / 47 |

4 / 40 |

||||

|

GD160 |

2 / 72 |

2.5 / 64 |

160 |

||

|

3 / 57 |

4 / 49 |

||||

|

GD185 |

2 / 85 |

2.5 / 74 |

185 |

DN150 |

|

|

3 / 66 |

4 / 56 |

||||

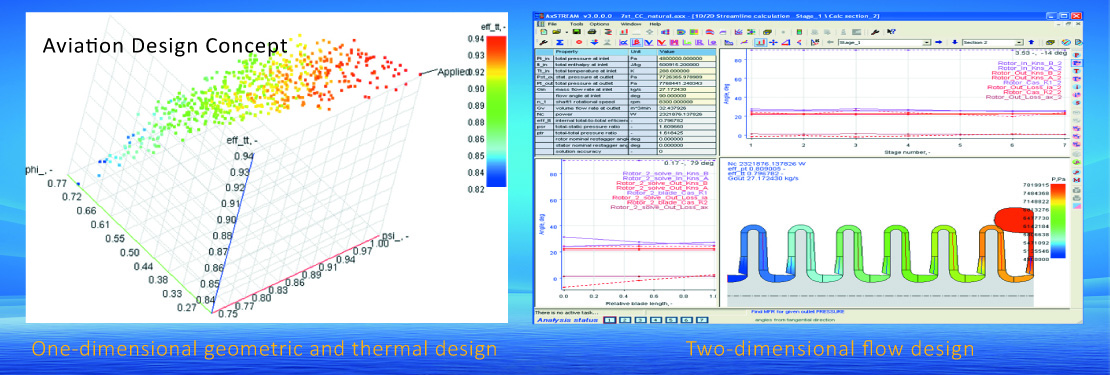

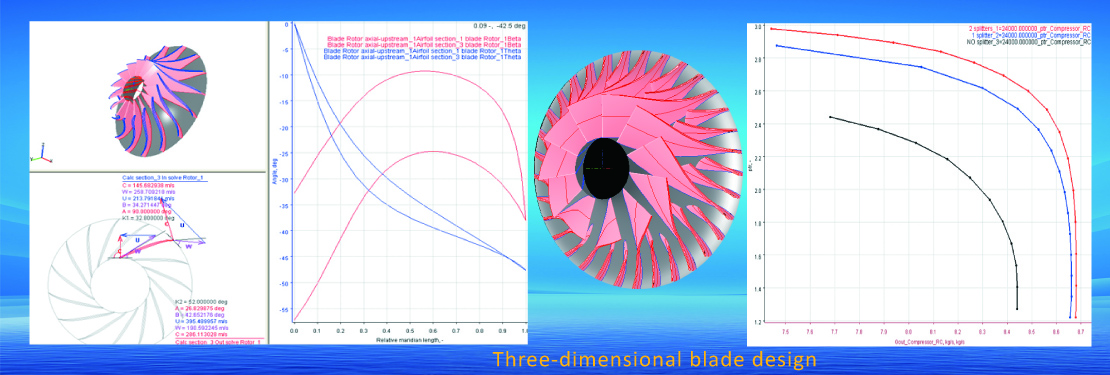

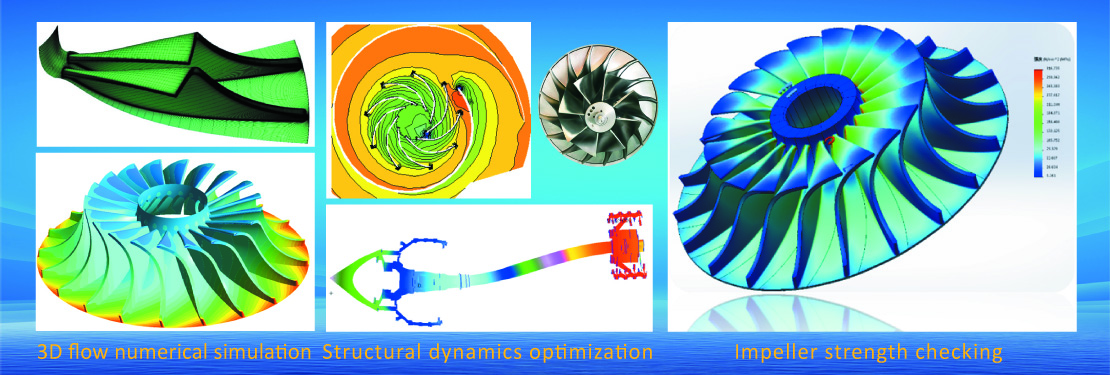

Aviation design concept – Impeller

Using finite element analysis software of NASTRAN, ANSYS, Abaqus, etc., to carry out one-dimensional geometric and thermal design, two-dimensional flow design, three-dimensional blade design and strength check of impellers and blades. Through simulation, it can be judged whether the impeller design meets the design standards of aero-engine, and the service life of the impeller can be predicted. Create high-efficiency aviation-grade impellers with the best “power energy efficiency ratio”.

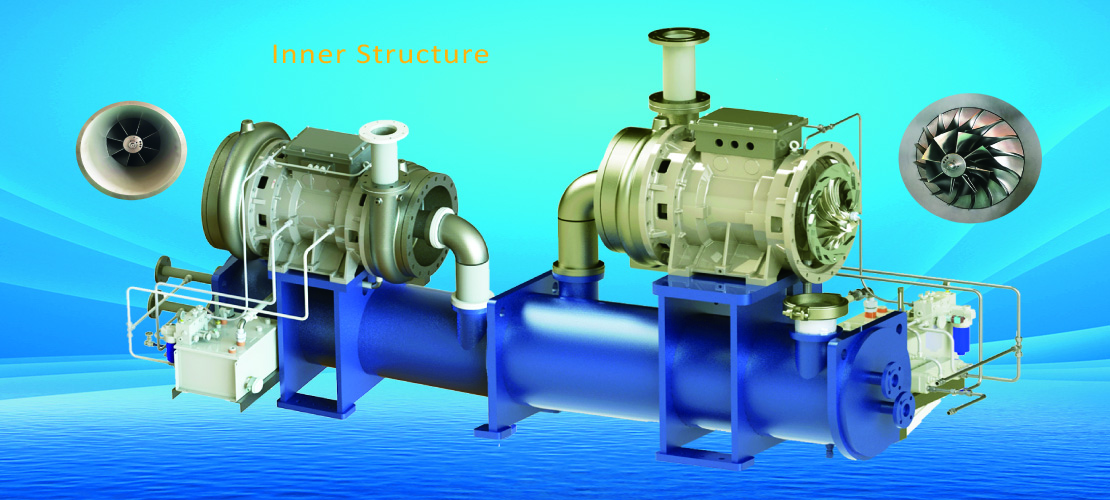

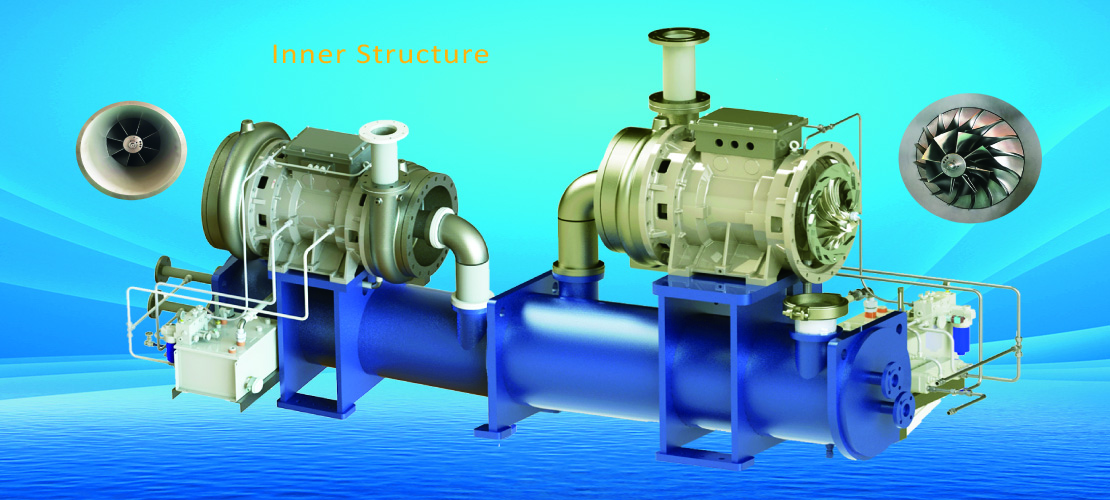

High-speed direct drive, integrated design

The high-speed motor is directly connected with impeller, the transmission efficiency is high, and noise is low.

》Impeller direct connection: No power loss of coupling and speed-up gearbox, high efficiency.

》Mature bearings: SKF ceramic bearings, overcomes the special working conditions where the suspension bearing is difficult to apply.

》Easy maintenance: Plate type high efficiency air filter, filter grade H12 or above, low pressure loss, high efficiency, and more convenient maintenance.

The high-speed motor is directly connected with impeller, without the power consumption of coupling and traditional reduction mechanism, with high transmission efficiency and low noise.

Novel and unique design

Unique structure, high-speed variable frequency direct drive motor + centrifugal impeller structure + cooling system + control system, the system is compact, and easy to install and maintain.

Large-screen display control, real-time monitoring of equipment operation & shutdown information, perfect combination of surge control and energy saving optimization, complete automatic alarm and protection functions, advanced and mature control system to ensure the stability of the compressor system and ease of operation. Intelligent control can be realized through the network.

》Easy installation: Box-type structure, no foundation, no alignment requirements, no need for calibration, and low requirements for the application environment.

》Frequency conversion adjustment: No peak current, stable start, wide adjustment range, stable pressure, and maintain the best working condition of the equipment.