Screw Vacuum Pump

Energy-saving Screw Vacuum Pump (Small vacuum system)

Screw vacuum pumps are widely used in electronics, printing and dyeing, foam, iron & paper printing, machining, photoelectric paper-plastic, blister packaging and other fields. It adopts frequency conversion intelligent control technology to realize automatic adjustment of flow and vacuum pressure according to process demand changes and reduce energy consumption. It is the preferred equipment for investment and energy-saving transformation of small and medium-sized vacuum system projects.

Screw vacuum pump adopts frequency conversion technology, the power can adjust with the change of production line parameters, and keeps vacuum pump always working in the best operating condition.

Vacuum system can be customized design according to client’s needs, the operation choose the most reasonable vacuum point, the vacuum degree proximity point, suction point is combined to make the vacuum pump always run in high-efficiency area of the characteristic line of the pump and the motor.

Vacuum system provides complete equipment and system solutions: cooler, filter, silencer, valves, meters, fittings and fully automated control system for online monitoring of vacuum degree and pumping flow.

|

Model |

Power (KW) |

Volume Flow Rate (M3/min) |

Ultimate Vacuum kPa(G) |

Connection |

Weight (KG) |

Dimension (L x W x H) mm |

|

SEV5A-100 |

5.5 |

6.5 |

-100 |

DN40 |

430 |

1200X1100X1250 |

|

SEV5A-080 |

6.3 |

-80 |

||||

|

SEV7A-100 |

7.5 |

9.6 |

-100 |

DN40 |

600 |

1200X1100X1250 |

|

SEV7A-080 |

9.5 |

-80 |

||||

|

SEV11A-100 |

11 |

12.5 |

-100 |

DN50 |

760 |

1400X1100X1450 |

|

SEV11A-080 |

12.0 |

-80 |

||||

|

SEV15A-100 |

15 |

15.0 |

-100 |

DN50 |

900 |

1500X1200X1650 |

|

SEV15A-080 |

14.6 |

-80 |

||||

|

SEV18A-100 |

18.5 |

18.0 |

-100 |

DN65 |

960 |

1500X1200X1650 |

|

SEV18A-080 |

17.6 |

-80 |

||||

|

SEV22A-100 |

22 |

22.5 |

-100 |

DN80 |

1100 |

1850X1450X1800 |

|

SEV22A-080 |

22.0 |

-80 |

||||

|

SEV30A-100 |

30 |

27.5 |

-100 |

DN100 |

1600 |

2150x1600x2100 |

|

SEV30A-080 |

27.0 |

-80 |

||||

|

SEV37A-100 |

37 |

30.5 |

-100 |

DN100 |

1850 |

2350x1700x2154 |

|

SEV37A-080 |

30.0 |

-80 |

||||

|

SEV45A-100 |

45 |

45.0 |

-100 |

DN125 |

1900 |

2350x1700x2154 |

|

SEV45A-080 |

44.5 |

-80 |

||||

|

SEV55A-100 |

55 |

60.0 |

-100 |

DN150 |

2200 |

3200x2150x2645 |

|

SEV75A-100 |

75 |

76.0 |

-100 |

DN200 |

3500 |

3200x2150x2645 |

|

SEV90A-100 |

90 |

85.0 |

-100 |

DN200 |

3600 |

3300x2250x2700 |

Energy-saving Screw Vacuum Pump (Small vacuum system)

— Save money, save trouble and save space

Screw vacuum pumps are widely used in electronics, printing and dyeing, foam, iron & paper printing, machining, photoelectric paper-plastic, blister packaging and other fields. It adopts frequency conversion intelligent control technology to realize automatic adjustment of flow and vacuum pressure according to process demand changes and reduce energy consumption. It is the preferred equipment for investment and energy-saving transformation of small and medium-sized vacuum system projects.

For large vacuum system, please visit the introduction of centrifugal vacuum pump

It adopts frequency conversion intelligent control technology to realize automatic adjustment of flow and vacuum pressure according to process demand changes and reduce energy consumption. It is the preferred equipment for investment and energy-saving transformation of small and medium-sized vacuum system projects.

Fully enclosed complete structure – all parts are installed in one cabinet, silencer and anti-vibration facilities are installed. It doesn’t need foundation, and it can be used after connecting the vacuum system pipe the power supply.

It can be customized according to the vacuum system parameters required by users, without special requirements, a single vacuum pump can be selected. The complete set of solutions can be configured with stainless steel or carbon steel internal coating separation tank, vacuum buffer tank, magnetic flap level gauge, automatic drainage controller, negative pump, cutting fluid storage tank, valves, pipe fittings and other system requirement.

Our goal is to become a leader in the research and development of large and small vacuum technologies, a provider of vacuum energy-saving solutions.

Comparison of energy consumption between screw vacuum pump and water ring vacuum pump

|

Parameter |

Volume Flow (M3/min) |

Actual Power (kW) |

|

3 sets of 15kw water ring vacuum pumps |

26.4 |

45 |

|

1 set of 37kw Screw vacuum pump |

30 |

25 |

|

energy consumption |

Actual Power |

Electricity (degree/year) |

|

kW |

24 hrs x 29 days x12 Months |

|

|

3 sets of 15kw water ring vacuum pumps |

45 |

375840 |

|

1 set of 37kw Screw vacuum pump |

25 |

208800 |

|

difference on total power, electricity |

20 |

167040 |

|

Saving ratio |

44% |

44% |

Save money, save trouble and save space

Save money: Compared with water ring vacuum pump or roots vacuum pump, it can save at least 160,000 kWh of electricity every year. If the electricity price is calculated at 0.7 yuan per kWh, it can save about 110,000 yuan in electricity costs and increase the flow rate by 12%, while reducing maintenance costs.

Save trouble: Avoid the trouble of waste water and noise treatment, worry-free and trouble-free! The most reasonable vacuum point design can be selected according to the operating conditions to make the production process more reasonable and efficient.

Save space: All components are installed in a cabinet, no need the foundation, cover a small area and saves site space, especially in buildings and industrial areas.

Core Technology Advantages - High Efficiency Airend (Patent No: CN201320374188.7)

SUCCESS ENGINE screw vacuum pump adopts the patented profile airend. By optimizing the rotor profile, the effective volume and sealing efficiency are improved, the contact line length, the leakage triangle area and the closed clearance volume are optimized. It completely solves the leakage of the oil and gas mixture during the rotor meshing process; the large diameter and low speed design, equipped with heavy-duty SKF bearings and three special oil seals, ensure the highest vacuum efficiency and service life, and greatly reduce the radial vibration and airflow noise.

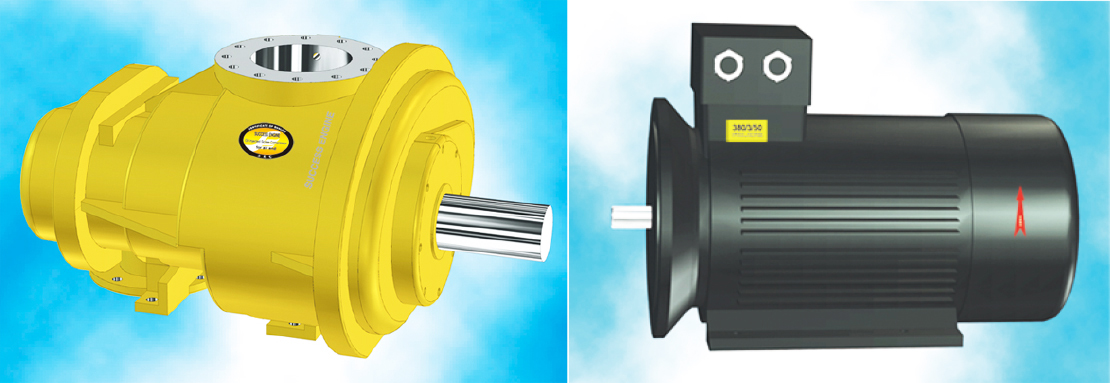

High-efficiency electric motor

Use special high output efficiency motor with high-quality bearings according to the site power supply and process conditions. The commonly used motors in China are generally 380V or 660V. Foreign users select corresponding motors according to local power supply voltage and frequency.

Efficient oil & air separation device and lubricating medium

Double-layer pleated oil-air separation element and rough oil & gas separation tank, ensuring the best oil and gas separation effect and the lowest system pressure difference.

SUCCESS ENGINE special cooling oil- MSDS (Material Safety Data) complies with the ISO 14001 environmental protection standard, high temperature resistance and anti-oxidation properties extend the life of core parts.

Ingenious vacuum system design

The optimal design of screw vacuum pump pipeline system and connection seal is related to the durable operation of equipment and vacuum pressure loss. SUCCESS ENGINE pays special attention to the system sealing effect and pressure difference, and carries out special optimal design from the sealing components to ensure the sealing and durability of the system.

Intelligent control (standard)

Adopt advanced intelligent control system with complete functions of automatic protection & alarm, remote control, multiple joint controls, history records.

》Real-time vacuum pump running data

》Energy consumption and loading / unloading characteristics can be monitored

》The parameter values can be reset according to the requirements of flow management

》Display and browse the preset status of each parameter

》History records checking and display maintenance warning

》The operation ,loading and unloading time can be accumulated and stored for a long time

》Continuously monitor, display and control the preset vacuum pressure and temperature

》Remote monitoring communication or linkage switching between multiple vacuum pumps

Atomically adjusts the frequency and speed according to the actual flow change to achieve effective energy savings, also with the characteristics of stable vacuum degree, stable startup, and variable flow, reducing energy waste and improving operation efficiency.

(Screw rotor testing)

(Advanced machining equipment)

(Manufacturing workshop)

(Poetic in SUCCESS ENGINE factory everywhere)